Chemical recycling

High-tech polymers are an essential element of modern industry and make up a high proportion of the mass of consumer goods, but their lifespan is steadily decreasing. The possibilities of recycling polymers are limited. Thus the increasing volume of plastic waste worldwide represents a major environmental challenge, and the elimination of end-of-use plastics is a key aspect of the path to an efficient closed-loop economy.

Innovative technologies are required to recover the highest possible amount of raw materials contained in the waste streams and to return them to material cycles. RECENSO has developed a process for industrial use that converts mixed plastic fractions into a liquid and universally usable hydrocarbon mixture. The CTC process (Catalytic Tribochemical Conversion) has the potential to play an important role in a wide range of applications worldwide.

CTC is a single-step catalytic liquefaction process characterized by its applicability to a variety of materials (e.g. agricultural waste biomass or mixed plastic waste). The combination of thermal, catalytic and physical forces for cracking hydrocarbon makes CTC unique and efficient. The produced oil can either be used for energy purposes or as secondary raw material in chemical/petrochemical industry. The latter enables the development of thus far untapped potentials. Material recycling in line with closed-loop economy becomes reality through the use of CTC.

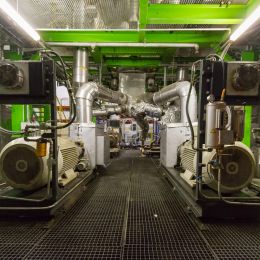

RECENSO, together with its partners, has created the world's largest pilot plant for the application of CTC. The design complies with international standards for industrial applications and is used for the testing and further development of the process in Germany. According to an international validation scheme CTC in the form of the pilot plant DIESELWEST is assigned a Technological Readiness Level (TRL) of 6/7 out of 9. It is one of the most advanced, cutting-edge applications worldwide.

RECENSO is engaged in the development and business of converting plastic-based input material under the CARBOLIQ brand. The company of same name is part of a network of international partners from science and industry. The pilot plant is available for demonstration and balancing of mass and energy flows.